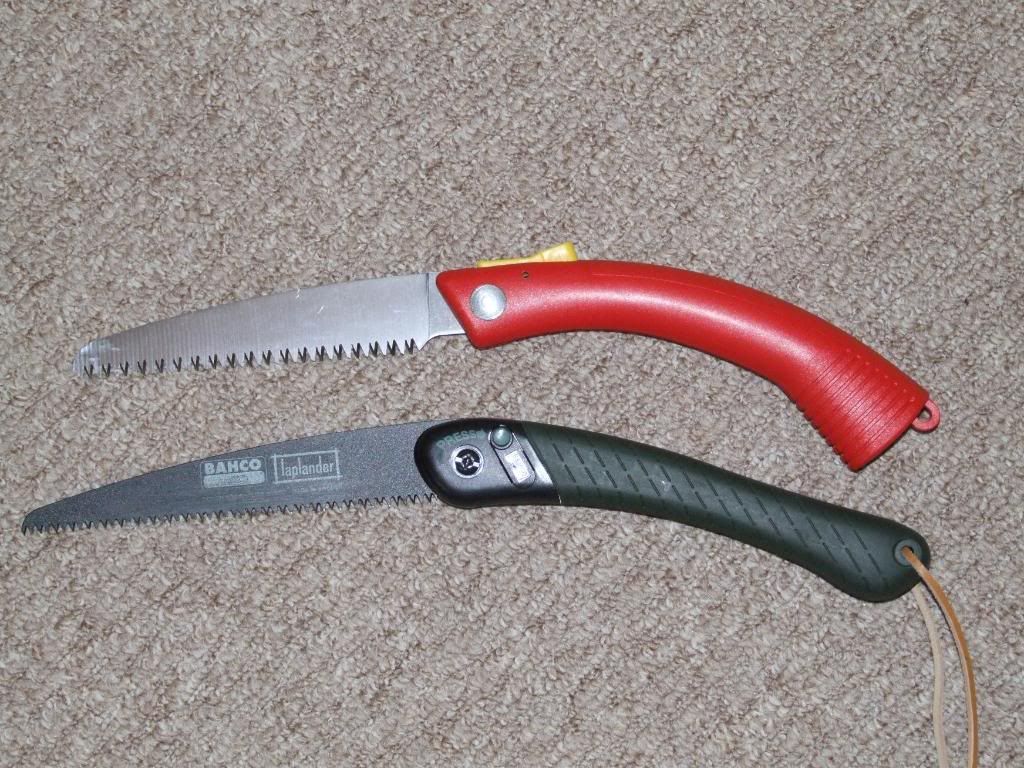

I found a nice folding saw in the shed and looking at, I belive I could re-handle it in solid wood...

The Laplander doesn't look like you can change the handle because of the way the lock works, but this one does.

It's a wolf garten folding saw... £18 on amazon, cuts really well and neatly too....

So I am going to attemt a solid oak or walnut folding saw! I think it would look great if i can do it. I have the wood and will rough it out tomorrow...Looks straight forward... But.... How am i going to cut the slot for the lock accuratly??? Chisles i guess...

Any suggestions???

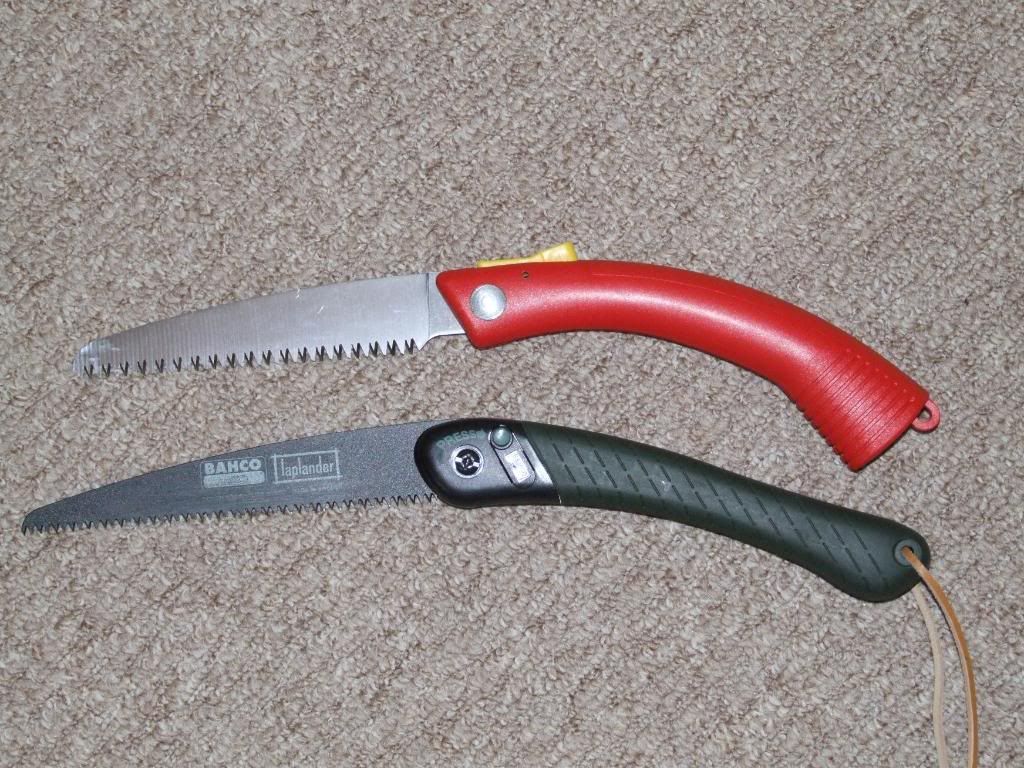

The Laplander doesn't look like you can change the handle because of the way the lock works, but this one does.

It's a wolf garten folding saw... £18 on amazon, cuts really well and neatly too....

So I am going to attemt a solid oak or walnut folding saw! I think it would look great if i can do it. I have the wood and will rough it out tomorrow...Looks straight forward... But.... How am i going to cut the slot for the lock accuratly??? Chisles i guess...

Any suggestions???