A few of my current projects! *watch this space.*

- Thread starter Samon

- Start date

-

Hey Guest, Early bird pricing on the Summer Moot (29th July - 10th August) available until April 6th, we'd love you to come. PLEASE CLICK HERE to early bird price and get more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks for kind words gent's.

I've got a few more knives to handle but I need a way to drill through hardened hss.. so it may be a while before I can get them done.

Tomahawk axe thing will be finished next, needs an edge which will take a while as it's like 4mm thick atm.. will be nice when it's complete though, just trying working on the rust finish.

I've got a few more knives to handle but I need a way to drill through hardened hss.. so it may be a while before I can get them done.

Tomahawk axe thing will be finished next, needs an edge which will take a while as it's like 4mm thick atm.. will be nice when it's complete though, just trying working on the rust finish.

Had some spare time earlier and the weather was nice, so I cracked on with the little tomahawk axe project.

I had left it to hand in the rain for weeks to form some actual rust to give it an aged look. I initially polished it to remove the paint so it had to be done to regain the look I wanted.

I decided today as it was doable with weather and all to sand off the rust to see how far down it had gotten and it was perfect!

So I ground in the new edge, polished it up, oiled it and cleaned up the handle.

Took an hour or so, was fun and I really like the finished axe. Small, light and can be taken down to pack easier.

I had left it to hand in the rain for weeks to form some actual rust to give it an aged look. I initially polished it to remove the paint so it had to be done to regain the look I wanted.

I decided today as it was doable with weather and all to sand off the rust to see how far down it had gotten and it was perfect!

So I ground in the new edge, polished it up, oiled it and cleaned up the handle.

Took an hour or so, was fun and I really like the finished axe. Small, light and can be taken down to pack easier.

Nice, the grain on that handle really pops. Did you do that thing with fire that you mentioned earlier?

Nice, the grain on that handle really pops. Did you do that thing with fire that you mentioned earlier?

Cheers dude, yeah I usually give it a quick whip over with a small blow torch before applying oil as it makes the grain expand and suck it in better. It also brings out some of the grain.

Nice little hawk that samon.......where does that door go?

Thanks!

That door opens to.. the land of fairies? atleast that what I tell my daughter lol.

Cracking little hawk there, it's hard to imagine that you could get such a beautiful tool from the ugly thing it started life as.

I appreciate all the kind words.

I've got a few more axe heads, one of which will be reshaped and tarted up, I was gona leave it as it is, but.. it's nothing fancy/pretty worthless atm and I do love playing with axes.

I've got a few more axe heads, one of which will be reshaped and tarted up, I was gona leave it as it is, but.. it's nothing fancy/pretty worthless atm and I do love playing with axes.

Got busy the last few days and knocked upa quick hair dryer air fed coal forge. And I must say, for 30 minutes work, it can reach high enough temperatures to literally melt carbon steel into mush.. which although was a mistake and a learning curve from leaving some scrap steel I was playing with in too long does make it possible for me to now smelt and cast brass!

SImple metal helium canister I had halved to make bbqs, but slotted back together, cut out a chimney hole and an air feed tube hole.

Excuse the firey picture, this was taken as the moist coal and wood was burning off before I could start actually using the hot coals.

Anyway, I have a bunch of old English files of good steel and although I've made them into knives before, I've never altered the existing heat treatment other than to temper them down. And I couldn't reshape them from straight to curved etc.

here are my first 3 basic blades from files. Left is a curved knife for a friend, was a slender but thick steeled file and is slightly inspired by oriental curved belt knives. I only forged in the tang as the original file tang kind of melted off on my first try lol. Middle is a slightly curved stick tang multi purpose knife bashed from a larger file. And lastly is a small thick file that I curved over as best I could considering my set up and is a single bevel/chisel edge mushroom knife! As you can see my 'anvil' is a sledge hammer sunk into a plank of 2x4". Works just fine for now too.

As you can see my 'anvil' is a sledge hammer sunk into a plank of 2x4". Works just fine for now too.

A quick profiling and shaping and some bevels etc..

I left enough meat on the edge as I hear the hardening temperature can distort or even melt thinner steel areas. And heated to non magnetic, dunked in cooking oil and then left in water once cooled enough.

Then something bad happened..

I was doing some extra grinding to tidy the profiles and bevels etc when the longest curved blade tip snagged on the inner wheel of my angle grinder flap disc, causing it to be flung back really hard into my hand. It passed through my leather kevlar lined gloves and into my paw pretty deep. I had to pull it out..

So although I got some scale and black crud removed from the other blades, this one has to be revisited before I temper it and the others.

Incase you want to see what happened..

The cut doesn't look bad there, but the tang of the long knife went into my hand about a cm and hit bloody hard! I'm going in for an xray tomorrow to make sure nothing is broken (feels fine to me) and to check there is no debris or kevlar fibres etc in my meaty wound.

Stay tuned for the rest. I will be winging the long knife with whatever handle material. The simple forged blade into soemthing a little nicer but still rustic to match and finally the mushroom knife in some antler!

Think I'll hand finish the ins and outs of the 3 blades with files and sandpaper while my hand heals.

SImple metal helium canister I had halved to make bbqs, but slotted back together, cut out a chimney hole and an air feed tube hole.

Excuse the firey picture, this was taken as the moist coal and wood was burning off before I could start actually using the hot coals.

Anyway, I have a bunch of old English files of good steel and although I've made them into knives before, I've never altered the existing heat treatment other than to temper them down. And I couldn't reshape them from straight to curved etc.

here are my first 3 basic blades from files. Left is a curved knife for a friend, was a slender but thick steeled file and is slightly inspired by oriental curved belt knives. I only forged in the tang as the original file tang kind of melted off on my first try lol. Middle is a slightly curved stick tang multi purpose knife bashed from a larger file. And lastly is a small thick file that I curved over as best I could considering my set up and is a single bevel/chisel edge mushroom knife!

A quick profiling and shaping and some bevels etc..

I left enough meat on the edge as I hear the hardening temperature can distort or even melt thinner steel areas. And heated to non magnetic, dunked in cooking oil and then left in water once cooled enough.

Then something bad happened..

I was doing some extra grinding to tidy the profiles and bevels etc when the longest curved blade tip snagged on the inner wheel of my angle grinder flap disc, causing it to be flung back really hard into my hand. It passed through my leather kevlar lined gloves and into my paw pretty deep. I had to pull it out..

So although I got some scale and black crud removed from the other blades, this one has to be revisited before I temper it and the others.

Incase you want to see what happened..

The cut doesn't look bad there, but the tang of the long knife went into my hand about a cm and hit bloody hard! I'm going in for an xray tomorrow to make sure nothing is broken (feels fine to me) and to check there is no debris or kevlar fibres etc in my meaty wound.

Stay tuned for the rest. I will be winging the long knife with whatever handle material. The simple forged blade into soemthing a little nicer but still rustic to match and finally the mushroom knife in some antler!

Think I'll hand finish the ins and outs of the 3 blades with files and sandpaper while my hand heals.

Ouch! Hope you heal well.

Other than that, good work with the forge. Looking forward to seeing the progress that you make.

Other than that, good work with the forge. Looking forward to seeing the progress that you make.

I do like the forge samon, very nice, you should be able to cast brass if it melts carbon steel. Good luck with the x ray too, lidls seem to still have the belt sander in.

Found some broken scissors in my junk drawer and fancied another go at a mushroom blade, just for the sake of it. I forged the tang area flat, symetrical and long, then chopped off the ring.

Gave the blades a polish earlier and a double check on the bevels etc, the first mushroom blade will not be getting tempered, it's hard and short. No need to worry about batoning through 6" mushrooms or anything anyway! And I mirror polished the edge for fun..

And I mirror polished the edge for fun..

I will oven the other 3 tomorrow?.. if I can bothered... :/ The long one that stabbed my hand is a sort of V grind convex as I don't use jgs and always free hand grind and the other one is a full convex.

The scissor blade is obviously stainless though, and although I blowtorch heat treated it earlier and water quenched it (oil didn't work the first few tries) I'm not really sure about the oven temper job. I'll just wing it as I always do and polish it properly another time as it was a last minute job cleaning off the ht scale.

Gave the blades a polish earlier and a double check on the bevels etc, the first mushroom blade will not be getting tempered, it's hard and short. No need to worry about batoning through 6" mushrooms or anything anyway!

I will oven the other 3 tomorrow?.. if I can bothered... :/ The long one that stabbed my hand is a sort of V grind convex as I don't use jgs and always free hand grind and the other one is a full convex.

The scissor blade is obviously stainless though, and although I blowtorch heat treated it earlier and water quenched it (oil didn't work the first few tries) I'm not really sure about the oven temper job. I'll just wing it as I always do and polish it properly another time as it was a last minute job cleaning off the ht scale.

Last edited:

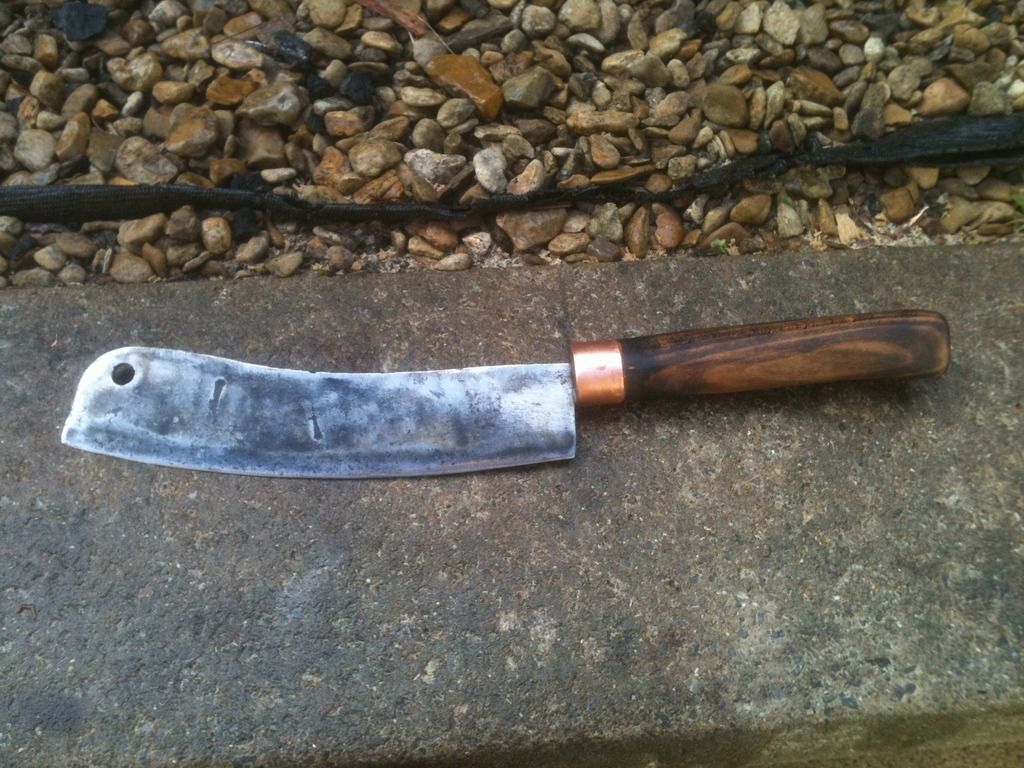

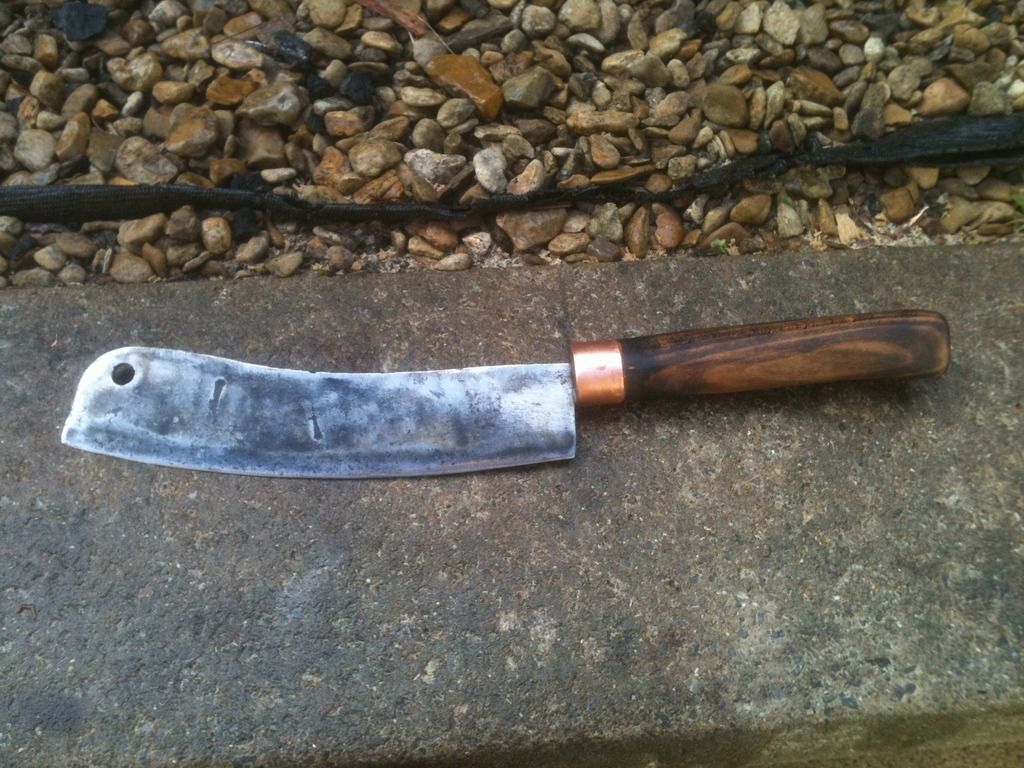

Between the constant unpredicable rain and personal things I managed one thing earlier. As mentioned here: http://www.bushcraftuk.com/forum/showthread.php?t=132535 One member was interested in a particular blade that I had cleaned up and I said I'd finish it asap. He also very kindly sent me some copper tubing to help assist my scrap builds.  And with some artful time useage I dodged most of the rain and got it finished!

And with some artful time useage I dodged most of the rain and got it finished!

Beach rolling pin, copper tube and blade.

A few tips when shaping round material into handle shapes using an angle grinder. Pencil on a rough shape to the material and Lay the gridner flat on your surface. Slowly work the material with both hands across the sanding wheel, in a sort of sharpening motion until it is flat on both sides. The redraw on the shape and do the other two potential sides. It takes a little eye balling and patience to get it eright without any accidental over the top grind divets. Proceed to knock off the straight edges untill it starts to become rounder.

I personally try to do as much as possible with the gridner then just sand to finish, but for cleaner and more predicable results use files to take off the extra bits and don't risk going too far with the grinder.

Anyway, here are some basic shots that show the early process.

Sadly I was interupted by heavy instant rain a few times, leaving me unable and really cheesed off to take more pictures of the copper collar fitting etc.

In short, I added the copper collar while it was red hot with a blow torch to get it to burn evenly onto the wooden handle. (don't have a lathe to get anything perfect, just my eyes)

Then I drilled a small hole in the collar for a copper pin once the blade was shoved into the handle. I also did this hot after a bit of drilling to get it to burn in. Some super glue and a peen on the copper pin to keep it all together has it nice and secure.

Handle got a quick sand, flame job and oil and it's done.

I don't bother trying to perfect the handles, I simply don't have the patience or the room needed to get them exact so I just rough them out and get them done. It may look alright but my intention isn't to tart up the handles, but just get one on.

If the weather permitts I'll do the other blade tomorrow in a similar way.

Thanks for reading!

Beach rolling pin, copper tube and blade.

A few tips when shaping round material into handle shapes using an angle grinder. Pencil on a rough shape to the material and Lay the gridner flat on your surface. Slowly work the material with both hands across the sanding wheel, in a sort of sharpening motion until it is flat on both sides. The redraw on the shape and do the other two potential sides. It takes a little eye balling and patience to get it eright without any accidental over the top grind divets. Proceed to knock off the straight edges untill it starts to become rounder.

I personally try to do as much as possible with the gridner then just sand to finish, but for cleaner and more predicable results use files to take off the extra bits and don't risk going too far with the grinder.

Anyway, here are some basic shots that show the early process.

Sadly I was interupted by heavy instant rain a few times, leaving me unable and really cheesed off to take more pictures of the copper collar fitting etc.

In short, I added the copper collar while it was red hot with a blow torch to get it to burn evenly onto the wooden handle. (don't have a lathe to get anything perfect, just my eyes)

Then I drilled a small hole in the collar for a copper pin once the blade was shoved into the handle. I also did this hot after a bit of drilling to get it to burn in. Some super glue and a peen on the copper pin to keep it all together has it nice and secure.

Handle got a quick sand, flame job and oil and it's done.

I don't bother trying to perfect the handles, I simply don't have the patience or the room needed to get them exact so I just rough them out and get them done. It may look alright but my intention isn't to tart up the handles, but just get one on.

If the weather permitts I'll do the other blade tomorrow in a similar way.

Thanks for reading!

Great stuff dude

i like that, looks like something an evenk nomad or saami might use

Cheers mate, it's crude, old and fitting I would say. I thought it had an oriental sort of look. Especially when I was hammering it into the handle and some of the tand was still showing, looked really japanese like one of their chef knives.

I really like that, it looks like you've been using it for years which is the idea I suppose

Sent from somewhere in a galaxy far far away...

Thanks mate! Old has it's own appeal, something I like, hence why I don't go the whole hog to shine most tools up and gve them the full works. Nice and simple users, that's my aim.

Similar threads

- Replies

- 7

- Views

- 231

- Replies

- 35

- Views

- 2K

- Replies

- 19

- Views

- 660

- Replies

- 8

- Views

- 391