Following up on Stanleythecats 'Home made tin can stoves;' thread

I came across this paper:

'A wood gas stove for developing countries' at

http://www.waoline.com/science/newenergy/BioEnergy/Links/WoodGasStove.pdf

As somebody seems to have spent some time working on a good design I thought I would have a go at making one and have actually found a suitable tin (often the most difficult part it seems to me).

But I can' t actually find one that has actually been made on the internet generally, the Biomass Energy Foundation website (where the authors of the paper came from or this site.

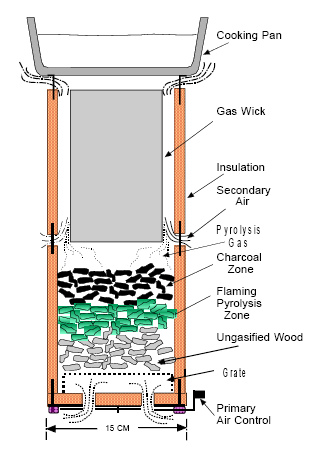

The schematic of the stove is:

and is pretty full. (The dimensions of the holes in the bottom and the 'Primary air control' are given separately in the paper.)

The main thing that I can think of that is missing is the size of the holes in the side - about half way up. As my general reading up on wood gas stoves suggests that size of holes can be crucial I was wondering if anyone has actually made one of these or can otherwise advise on size of these holes?

Also has anybody made one which includes the insulation? And if so what did they use?

I came across this paper:

'A wood gas stove for developing countries' at

http://www.waoline.com/science/newenergy/BioEnergy/Links/WoodGasStove.pdf

As somebody seems to have spent some time working on a good design I thought I would have a go at making one and have actually found a suitable tin (often the most difficult part it seems to me).

But I can' t actually find one that has actually been made on the internet generally, the Biomass Energy Foundation website (where the authors of the paper came from or this site.

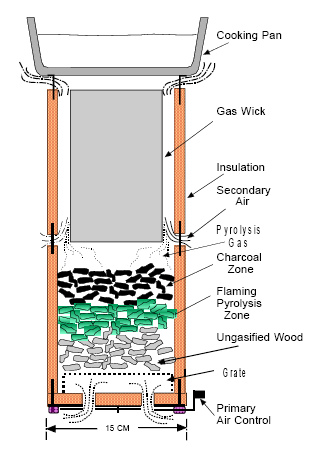

The schematic of the stove is:

and is pretty full. (The dimensions of the holes in the bottom and the 'Primary air control' are given separately in the paper.)

The main thing that I can think of that is missing is the size of the holes in the side - about half way up. As my general reading up on wood gas stoves suggests that size of holes can be crucial I was wondering if anyone has actually made one of these or can otherwise advise on size of these holes?

Also has anybody made one which includes the insulation? And if so what did they use?